Medical : After Petri Dishes... Pipette tips and other MDs

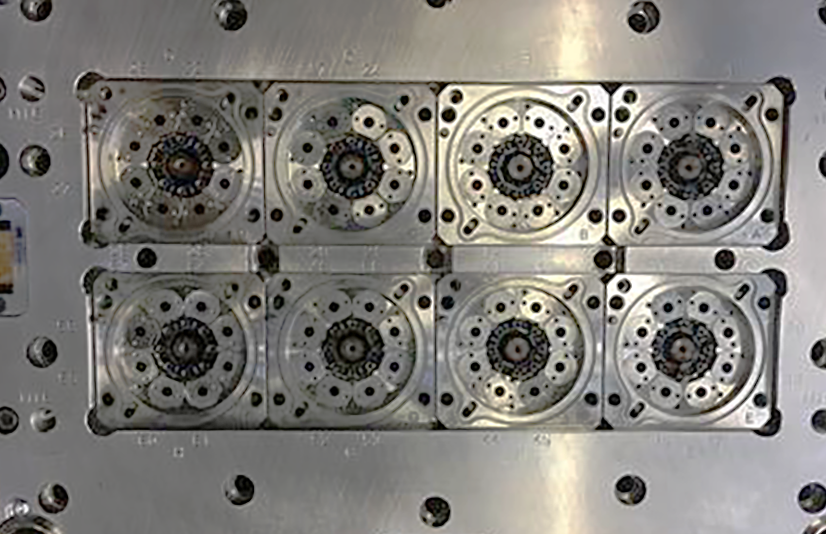

Plastisud has been involved in the Medical sector since the very beginning, with national and international companies. Thus we have built a solid reputation, year after year, particularly in the field of Petri dishes used in diagnosis. Our company now occupies a position as a recognized leading mold maker for these boxes of different diameters, with molds from 4+4 to 16+16 cavities, in production all around the world.

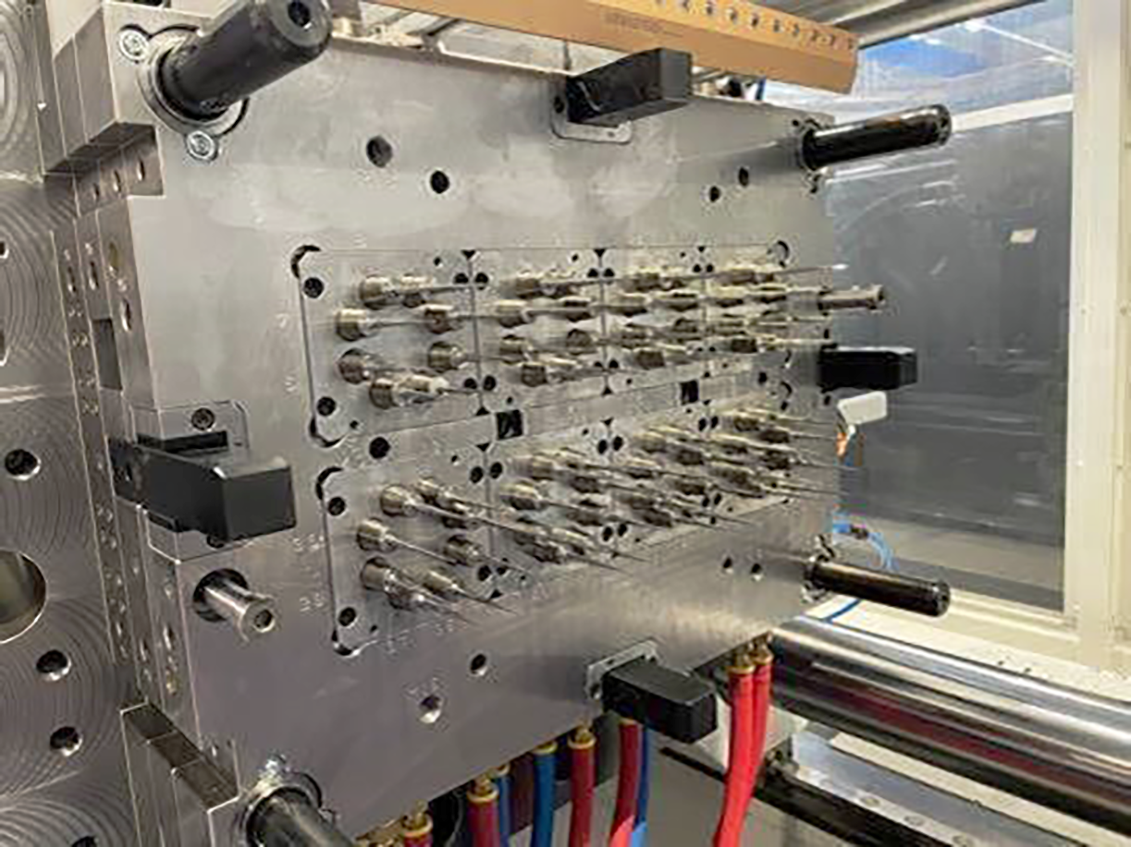

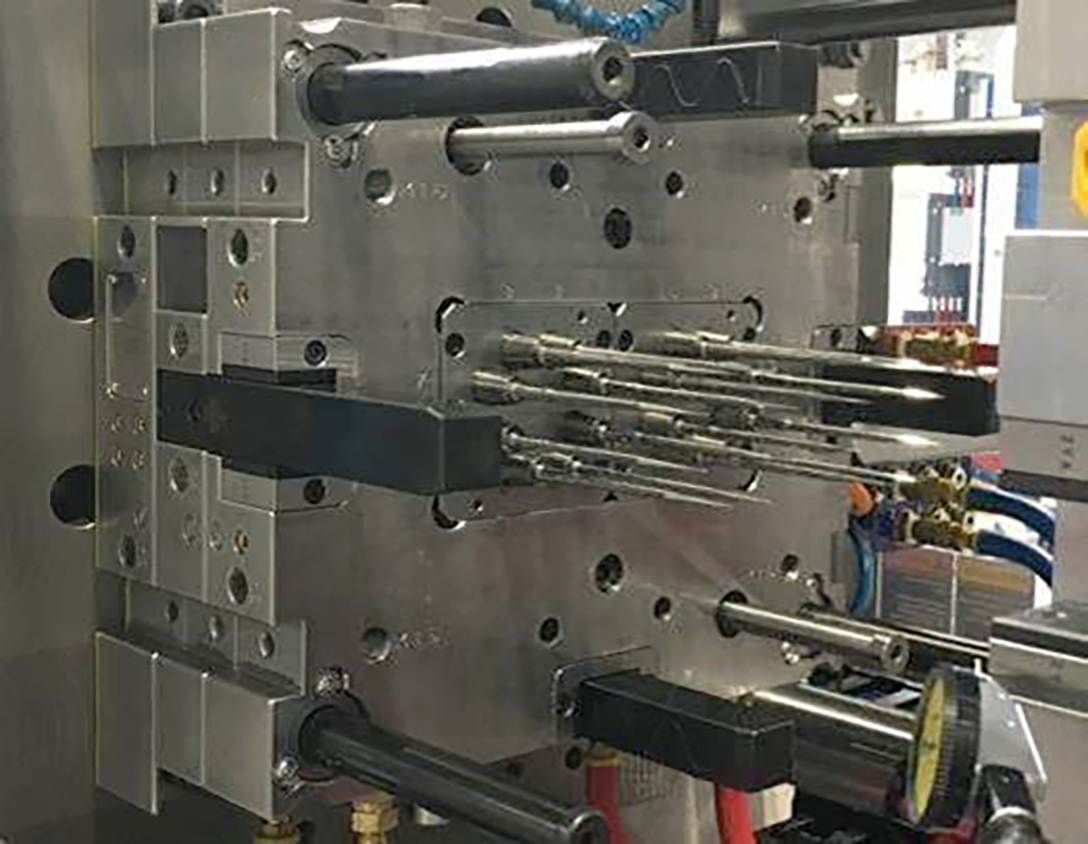

More recently, we wanted to diversify into other markets requiring large volumes and requiring tight machining tolerance. We decided to study and develop molds for Pipette Tips, which are just as demanding in terms of precision and repeatability.

For our latest generation machines equipped with robots, which allow the launch of large series, these parts are no longer a challenge. Our experience and know-how allow us to master the run-out on plastic parts and the deflection imposed by the automation equipment used for the tests.

Since our development phase with an 8-cavity pilot mold and a 64-cavity production mold (exhibited at various shows), we acquired 3 years of experience. By doing so, we gained the trust of several major players in this niche, with delivery times in line with their expectations.

In view of the global health situation, requests are increasing. Today we have built about twenty molds for Pipettes from 70 ul to 1250 ul and more are in progress and to come.

In the medical sector, our skills also extend to other devices such as: nasal pumps, sprays, syringes and their environment (needle protectors, caps, tubs and nests)…

We are strongly committed and continue to develop this activity. More than ever, our clients rely on expert and responsive professionals to support them in their new projects.