Closures

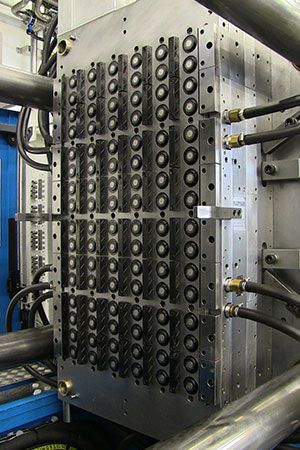

We are specialized in CAP moulds with short cycle times, high productivity, up to 144 cavities.

We offer no STANDARD but only TAILOR-MADE CAPS, with co-development, as per your design.

Regardless of the diameter, the tamper-evident band, 1-, 2- or 3-piece cap, sport cap, hinged, in-mould closure, tethered cap ... we are market leaders in many fields and help you finalize your project successfully.

Thanks to our unitary cell dedicated to pilot moulds, rework is done almost in real time and we are extremely responsive.

Tethered Cap Moulded band

mould

96 cavities

weight

1,2 g

hot runner

Plastisud - Hot tips

resin

HD PE

charactéristics

1st tethered cap available on the market : co-development and manufacturing of production moulds

Sport Cap 1-piece

mould

24 cavities

weight

2,95 g

hot runner

Plastisud - Hot tips

resin

HD PE

charactéristics

In mould closing

26 mm Cap Slitted & folded band

mould

96 cavities

weight

0,9 g

hot runner

Plastisud - Hot tips

resin

HD PE

charactéristics

Safety band slitted and folded outside of the mould

29/25 Cap Moulded band

mould

96 cavities

weight

1,3 g

hot runner

Platisud - hot tips

resin

HD PE

charactéristics

Cycle below 2 seconds

Sport Cap 1-piece

mould

32 cavities

weight

2,6 g

hot runner

Plastisud -hot tips

resin

HD PE

characteristics

In mould closing

3-piece Cap Carton package

mould

48 cavities

weight

Base : 1,6 g

Cutter : 0,5 g

Lid : 1,5 g

resin

Base : PP

Cutter : PP

Lid : HD PE

28 mm CSD Cap Slitted & folded band

mould

96 cavities

weight

1,2 g

hot runner

Platisud - hot tips

resin

HD PE

charactéristics

Safety band slitted and folded outside of the mould