KNOW-HOW

Pilot Workshop

Because your deadlines are tight and time to market is critical, we listened to your requirements and configured our workshop accordingly, organizing a production cell dedicated to "unitary" work.

A complete set of Machines dedicated to pilot moulds and to the rework on stacks for tests make it possible to manufacture and modify in record times, so that you make the right launch decisions on your production moulds.

We fine-tune with you the performance of your plastic part and carry out dimensional rework in no time.

Plastisud advantages

Trial Lab

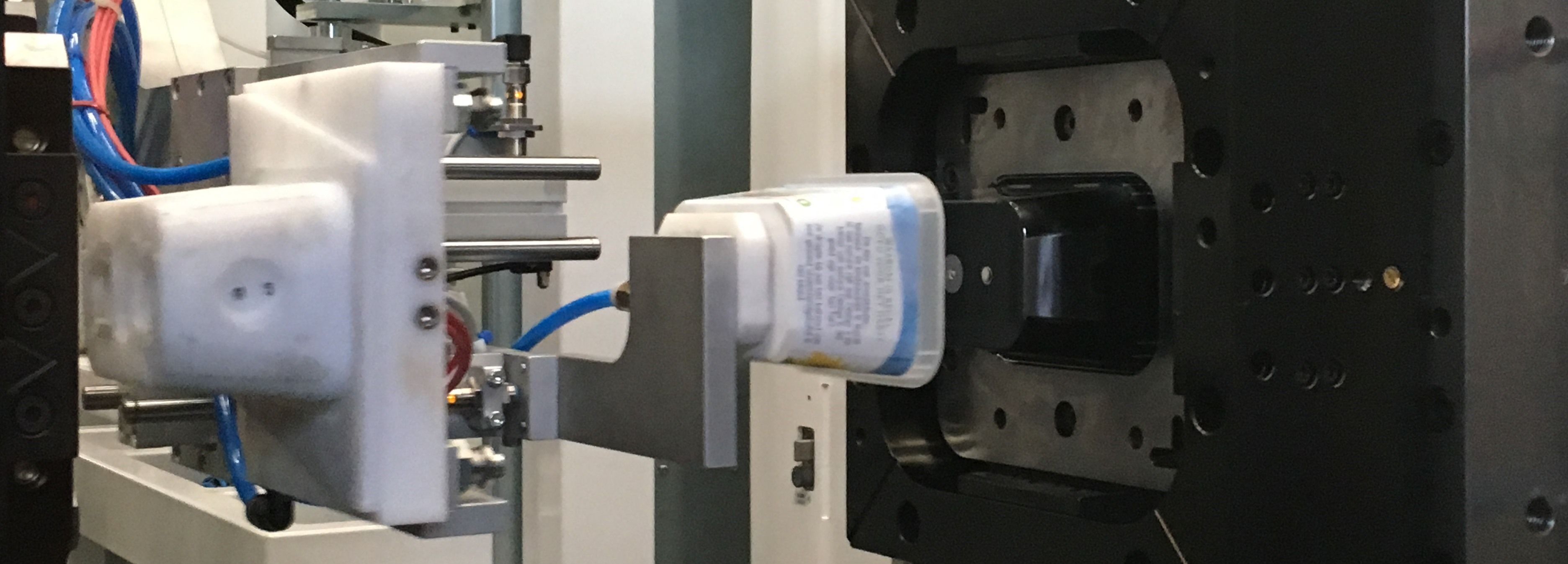

Before shipment, your moulds are validated and tested in our laboratory in one of our 12 injection machines. Sampling is done according to your acceptance protocol.

We run your pilot moulds and co-developments on dedicated machines (equipped with robots) in extreme short time and provide you with good plastic parts and moulds in the best time-frames.

Our Trial Lab

Integration and qualification

Plastisud can integrate your complete systems in a dedicated space inside our test lab. We receive your machine and your robot, we install our mould, and start up the system for an optimized debugging in our workshop.

When qualifying the mold in your presence, our Quality Control Department carries out dimensional reports on our latest generation measuring equipment. Control sheets and samples are given to you for your own tests.

Plastisud Advantage

Maintenance and overhaul

Throughout the life cycle of your mould, Plastisud accompanies you in the maintenance and service: diagnosis, technical support, repair, conversion, spare parts ...

After several million cycles, we carry out the complete overhaul and refurbishment.