Packaging

We build single face and stack moulds up to 12 + 12 cavities, for THIN WALL parts (≤ 0.30 mm for containers).

We integrate our own hot runner systems for a a perfect balance of the mold, at the best cycle times in the industry.

Our R&D team explores new mold technologies and process with eco-friendly resins (PLA, PET, bio-sourced materials...).

Our "Injection/Compression" Patent for stack molds is a real solution to save additional weight on your part !

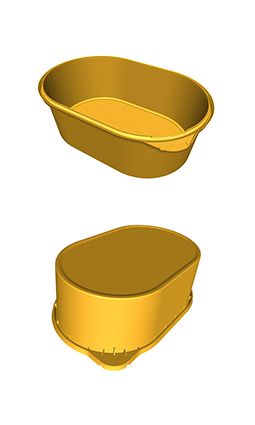

Tub GN1/4 Injection/Compression Technology

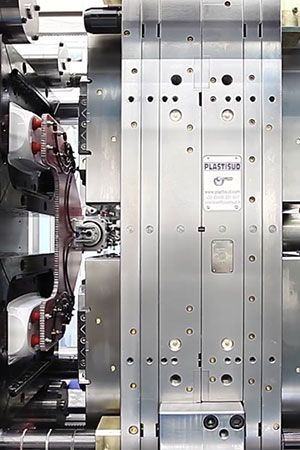

mould

Stack mould 2+2 cavities

weight

22,9 g

hot runner

Plastisud - Valve gate

resin

PP - Mfi 20

characteristics

Plastisud Patent for Injection / Compression on stack moulds

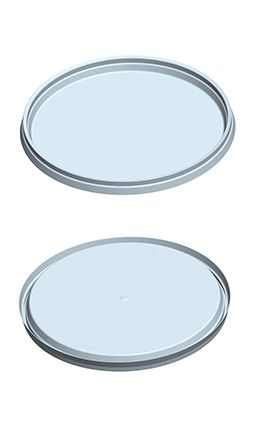

Round Lid Ø 131 mm Injection/Compression Technology

mould

Stack mould 8+8 cavities

weight

7,6 g

hot runner

Plastisud - Valve gate

resin

PP

characteristics

Plastisud Patent for Injection / Compression on stack moulds

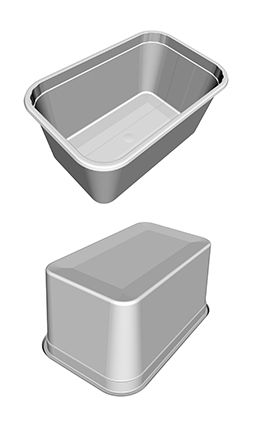

Container 500 g - IML

mould

Stack mould 6+6 cavities

weight

14,6 g

hot runner

Plastisud - Valve gate

resin

PP

characteristics

Take out with robot

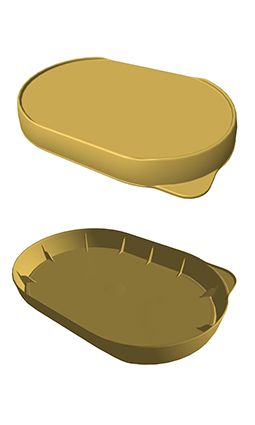

Round Lid Ø 143 mm – 2 colours

mould

Stack mould 6+6 cavities

weight

12 g

hot runner

Plastisud - Valve gate

resin

PP

characteristics

Take out with robot

Lid 1kg - IML

mould

Stack mould 2+2 cavities

weight

18,5 g

hot runner

Plastisud - Valve gate

resin

PP

characteristics

Take out and label positionning with robot

Container 1kg - IML

mould

Stack mould 2+2 cavities

weight

28,5 g

hot runner

Plastisud - Valve gate

resin

PP

characteristics

Take out and label positionning with robot

Round Lid Ø 73 mm – Safety band

mould

Stack mould 12+12 cavities

weight

5,7 g

hot runner

Plastisud - Hot tips

resin

LD PE

characteristics

Take out in guiding rails

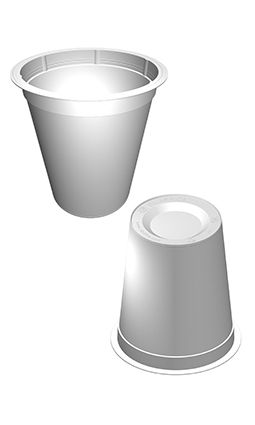

Round Container 150g Injection/compression Technology

mould

8 cavities

weight

5,9 g

hot runner

Plastisud - Valve gate

resin

PP

characteristics

Take out with robot